Latest News

Which Welding Blanket Is Right for You?

Posted on 09/02/2026

In this guide, we compare three popular options from Cepro - Asteria, Kronos and Thetis and answer common questions such as are welding blankets fireproof, what is a welding blanket used for and how to choose a welding blanket for metal fabrication.

What Is a Welding Blanket Used For?

A welding blanket is designed to protect surrounding areas during welding, cutting and grinding operations. It helps to:

- Contain sparks and spatter

- Reduce fire risk

- Shield machinery, floors and workpieces

- Provide heat and flame resistance in welding environments

A blanket for welding can be used horizontally to cover surfaces or vertically as a curtain or screen, depending on the material and coating.

Are Welding Blankets Fireproof?

This is a common question and the short answer is: welding blankets are fire resistant, not fireproof.

High-quality fire resistant blankets are made from fibreglass and treated coatings that will not ignite under normal welding conditions. Products like the Cepro Asteria, Kronos and Thetis are non-flammable and tested to EN 13501-1 fire safety standards, but they still have maximum temperature limits that should always be respected.

How to Choose a Welding Blanket for Metal Fabrication

When choosing the right heat resistant blanket, consider the following:

- Temperature Resistance

- Light welding and grinding = lower temperature rating

- Heavy fabrication or high heat exposure = higher temperature rating

- Weight & Durability

- Lighter blankets are easier to handle

- Heavier blankets offer better abrasion and heat resistance

- Application

- Horizontal protection (floors, benches, machinery)

- Vertical use (screens, curtains, partitions)

This is where understanding the differences between Asteria, Kronos and Thetis really matters.

Thetis vs Kronos vs Asteria: What’s the Difference?

Cepro Asteria Welding Blanket - Best for Light Workshop Use

The Asteria welding blanket is a medium-weight option designed for light welding and grinding tasks.

Key benefits:

- Temperature resistance up to 550°C (600°C peak)

- Suitable for vertical use

- Lightweight and easy to handle

- A1 fire-rated and non-flammable

Best for:

General workshop welding, light fabrication, maintenance work and temporary protection.

Cepro Kronos Welding Blanket – Best for Vertical Applications

The Kronos welding blanket features a PU-coated fibreglass surface with aluminium pigments, making it ideal for use as a welding or grinding curtain.

Key benefits:

- Temperature resistance up to 550°C (600°C peak)

- PU coating improves durability and anti-slip performance

- Excellent resistance to fraying

- Specifically recommended for vertical use

Best for:

Welding bays, partitions, grinding screens and areas where a hanging fire resistant blanket is needed.

Cepro Thetis Welding Blanket – Best for High-Temperature Protection

The Thetis welding blanket is the heavyweight option in the range, designed for demanding, high-temperature environments.

Key benefits:

- Continuous temperature resistance up to 700°C

- Peak resistance up to 900°C

- Heavyweight 1,100 g/m² fibreglass cloth

- Dual-sided graphite coating for maximum durability

- Suitable for horizontal and vertical use

Best for:

Heavy fabrication, industrial welding, high-heat applications and situations where maximum protection is required.

Best Welding Blankets for High-Temperature Protection in the UK

If you’re working with higher heat levels, the Cepro Thetis welding blanket is the best choice due to its superior temperature resistance and abrasion protection. For lighter tasks or curtain-style use, Kronos and Asteria offer reliable, cost-effective alternatives.

All three options are manufactured to meet UK and EU fire safety standards, making them suitable for professional use across workshops and industrial sites.

Benefits of Using a Welding Blanket

Using the correct welding blanket helps to:

- Reduce fire risk

- Protect expensive machinery and tools

- Improve workshop safety

- Contain sparks and spatter

- Maintain compliance with health and safety standards

In many cases, using a heat resistant blanket is a simple but effective way to prevent costly damage and downtime.

Difference Between a Welding Blanket and a Fire Blanket

Although they may look similar, they serve different purposes:

- Fire blankets are designed to extinguish small fires

- Welding blankets are designed to prevent fires by containing heat and sparks

A welding blanket should always be used during welding or grinding operations, rather than relying on a fire blanket alone.

Where Can I Buy Welding Blankets in the UK?

You can buy welding blankets in the UK online from specialist welding suppliers. Look for:

- Certified fire ratings (EN 13501-1)

- Clearly stated temperature limits

- Multiple size options

- Reputable manufacturers like Cepro

Buying from a welding specialist ensures you get the correct blanket for welding based on your application.

View our welding blankets here.

Final Thoughts: Which Welding Blanket Should You Choose?

- Choose Asteria for light welding and everyday workshop use

- Choose Kronos for vertical protection and welding curtains

- Choose Thetis for high-temperature and heavy-duty applications

Understanding the differences ensures you get the right balance of safety, durability and performance for your work.

The Ideal Spot Welder For Automotive Work

Posted on 02/02/2026

In automotive repair and restoration, precision isn’t just a ‘nice to have’, it’s essential. Whether you’re repairing body panels, restoring a classic car or carrying out modern collision repairs, choosing the right spot welder can make a noticeable difference to both the finish and the time spent on each job. That’s where the Telwin Digital Modular 230 Handheld Spot Welder stands out…

The Telwin Digital Modular 230 Handheld Spot Welder was designed specifically with automotive applications in mind. This advanced spot welding machine delivers consistent, professional results while remaining compact, portable and easy to use.

Built for Automotive Spot Welding

Automotive panels are often thin, coated, galvanised or made from high-strength steel. A standard welder simply won’t offer as much control for these materials as a spot welder would. The Telwin Digital Modular 230 is a purpose-built automotive spot welder, engineered to handle exactly these challenges.

Its integrated microprocessor and advanced Fuzzy Logic technology automatically adjust welding current and time based on material thickness. This removes guesswork, reduces burn-through and ensures clean, repeatable welds even when working on delicate body panels. This automated technology also means this spot welder is very beginner friendly.

For workshops handling a mix of classic restorations and modern vehicle repairs, this level of automation is a real time-saver.

A Truly Portable Spot Welder

Space and mobility matter in busy workshops. Weighing just 10.5 kg, the Telwin Digital Modular 230 is a genuinely portable spot welder that can be easily moved between workstations or taken directly to the job.

Its ergonomic, thermally insulated handgrip and adjustable arm pressure (40–120 kg) allow comfortable use throughout the working day, helping reduce fatigue while maintaining consistent weld quality.

Reliable 240V Power for UK Workshops

Running on a standard 240V spot welder supply (230V single phase), the Digital Modular 230 fits seamlessly into UK automotive workshops without the need for specialist electrical installations.

Despite its compact size, it delivers an impressive maximum spot-welding current of 6900A, allowing it to weld up to 2 + 2 mm sheet metal with confidence - more than enough for most automotive repair and restoration tasks.

Why Professionals Choose the Telwin Digital Modular 230

For automotive professionals, the appeal of this spot welding machine comes down to three things: control, consistency, and convenience.

- Consistent welds across a wide range of materials

- Reduced setup time thanks to automatic regulation

- Compact, lightweight design without sacrificing performance

Whether you’re running a body shop, restoration workshop or fabrication business, the Telwin Digital Modular 230 offers a dependable solution that delivers high-quality results job after job.

View the Telwin Digital Modular 230 Handheld Spot Welder on our website and see how the right spot welding machine can elevate your automotive work.

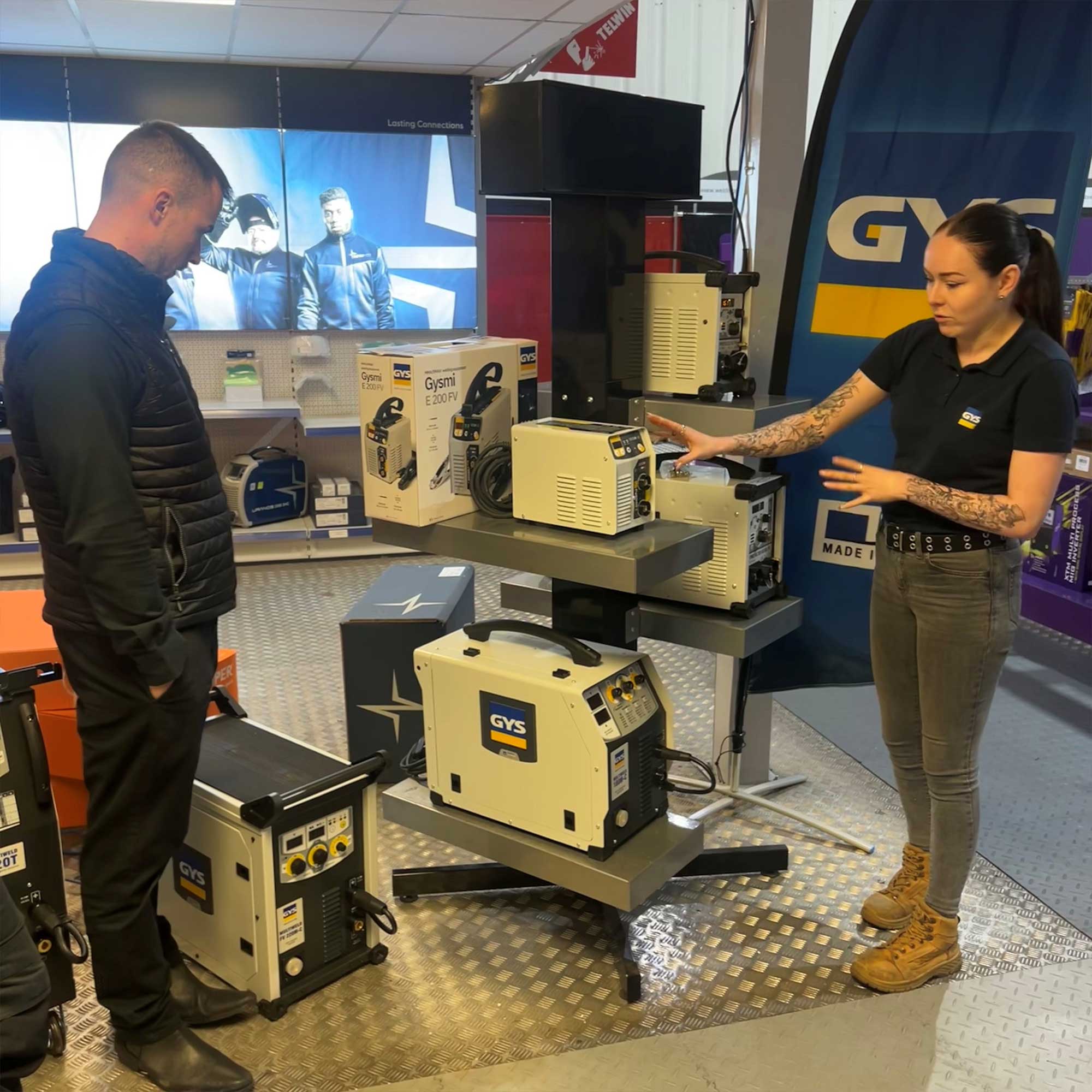

GYS Welders Now Available Online at Welding Superstore

Posted on 26/01/2026

We’re pleased to announce that GYS welders are now available to purchase online at Welding Superstore. Following strong interest in our Telford showroom, our range of GYS welding machines are now accessible nationwide through our website, making it easier than ever to find the right machine for your workshop or site

A Trusted Name in Welding - GYS Welding UK

GYS is a globally recognised manufacturer, known throughout the UK welding market for producing reliable, innovative and user-friendly welding equipment. Their machines are widely used across fabrication, automotive repair, maintenance and industrial environments, offering performance you can depend on day after day.

At Welding Superstore, we stock a growing range of GYS welders including MIG, TIG and MMA machines, as well as plasma cutters and induction heating technology. Whether you’re upgrading existing equipment or investing in your first professional machine, GYS offers solutions to suit a wide range of applications and experience levels.

GYS MIG, TIG, MMA, Plasma & Induction Heating Solutions

Our current GYS range includes:

- GYS MIG welder options for smooth, controlled wire feeding and consistent weld quality

- TIG and MMA welders suitable for precision work and site use

- Plasma cutters for fast, clean cutting of conductive metals

- GYS induction heater technology for safe, flameless heating of metal components

Popular machines such as the MULTIWELD and KRONOS series combine advanced inverter technology with intuitive controls, making them a strong choice for both professionals and developing welders.

View our full range of GYS welders.

In‑House Training Direct from GYS

To ensure we can offer expert advice, GYS recently visited our Telford showroom to deliver in-depth product training to our team. The session covered a wide range of machines, features and real-world applications, allowing us to better understand how each model performs in different environments.

We also saw live demonstrations of key equipment, including induction heating solutions and synergic welding machines with pre-programmed settings. This hands-on training means our team is well equipped to guide customers towards the most suitable GYS welder for their needs.

Visit Our Telford Showroom or Buy Online

Many GYS machines are available to view in person at our Stafford Park showroom, where selected models can be demonstrated on request with prior notice. If you prefer to buy online, many GYS machines are now available to order directly through our website, with nationwide delivery available.

If you’re unsure which machine is right for you, our trained team is always happy to help.

Explore GYS welders online today and discover why GYS continues to be a leading name in welding equipment across the UK.

MIG, TIG & MMA Welding Courses – 1 Day Classes in Telford

Posted on 19/01/2026

Want to build practical welding skills without committing to a long- term qualification? Our one day basic welding course could be exactly what you are looking for!

These hands-on courses are designed to be suitable for every skill level – whether you’re a complete beginner with absolutely no experience or a welder who wants to feel more confident behind the torch – our trainer tailors the course completely to your experience level.

Our short courses are all about practical learning, not classroom theory.

Why Choose a 1 Day Welding Course?

Not everyone wants (or needs) a multi-week qualification. A one day welding course is ideal if you:

- Want to learn the basics quickly

- Need welding skills for DIY, maintenance or fabrication work

- Are considering welding as a career and want to try it first

- Already weld but want to improve technique or confidence

You’ll spend the majority of the day actually welding with expert guidance throughout - no wasted time, no pressure.

Following this course, you will receive a certificate of attendance – if you are after industry recognised qualifications, we recommend checking out our coded courses.

MIG, TIG or MMA – Which Welding Course Is Right for You?

If you're not sure which process to choose, here’s a quick breakdown.

MIG Welding Course (Metal Inert Gas)

A MIG welding course is usually the most popular option for beginners. MIG welding is easier to learn, forgiving and widely used in fabrication, automotive work and general workshop environments.

Perfect if you want quick results and a strong foundation.

Find out more & book MIG Welding Courses here.

TIG Welding Course (Tungsten Inert Gas)

TIG welding courses are ideal if you want precision and control. TIG welding is more technical than MIG but produces cleaner, higher-quality welds.

This course suits those looking to develop skill and finesse.

Find out more & book TIG Welding Courses here.

MMA Welding Course (Manual Metal Arc / Stick Welding)

An MMA welding course (also known as stick welding) is great for outdoor work, repairs and heavier fabrication.

MMA welding is tough, versatile and still widely used across many industries.

Find out more & book MMA Welding Courses here.

What to Expect on the Day

Our welding courses in Telford are relaxed, friendly and focused on learning by doing.

When you arrive, you’ll start by having a cuppa and a group chat with our instructor so he can understand what your skill level is like and what you are hoping to achieve from the course.

Following this, you’ll get stuck in with welding pretty quickly – our trainer will talk you through some theory such as welding safety, machine settings, techniques etc and once you feel comfortable and confident, the welding will commence.

Our trainer will remain close by and provide tips and guidance as you crack on with your welds.

No prior experience is needed - everything is explained clearly, step by step to a pace that suits you.

Why Take a Welding Course in Telford?

Telford is easily accessible from across Shropshire, the West Midlands and surrounding areas, making it a convenient location for professional welding training without travelling too far. We have trainees travel from all across the country to attend our welding school.

Our workshop-based courses give you real-world experience, not just theory - using the same type of equipment found in working fabrication environments. We believe in a much more hands-on approach, rather than hours of classroom theory.

Ready to Book a Welding Course?

If you’re looking for practical, one day welding courses in Telford, our MIG, TIG and MMA classes are a great way to build skills fast and gain confidence with professional equipment.

Whether you’re welding for work or for yourself, learning the right techniques makes a huge difference.

Book your welding course directly on our website or contact us for help finding which option is best for you.

What is the difference between MB15, MB25 and MB36 MIG torches?

Posted on 12/01/2026

Choosing the right MIG torch is vital to get the highest quality welds from your welder. The torch directly affects weld quality, operator comfort and how reliably you can work at different amperage levels.

In this article, we’ll break down the key differences between Parweld MB15, MB25 and MB36 MIG torches, explain what each one is best suited for and help you decide which torch is right for your welding setup.

What Do MB15, MB25 and MB36 Mean?

The MB numbering system refers primarily to the current capacity (amperage rating) of the MIG torch. As the numbers increase, so does the torch’s ability to handle higher welding currents and heavier-duty applications.

In simple terms:

- MB15 – Light-duty MIG torch

- MB25 – Medium-duty MIG torch

- MB36 – Heavy-duty MIG torch

Each step up offers higher amperage handling, improved cooling and more robust construction.

Parweld MB15 MIG Torch – Lightweight & Easy to Handle

The Parweld MB15 MIG torch is designed for light-duty welding and is commonly supplied with smaller MIG machines.

Key Characteristics:

- Rated at 140 amps (depending on duty cycle and gas)

- Slim torch neck and lightweight cable

- Excellent manoeuvrability and control

Best For:

- Automotive repairs

- Light fabrication

- DIY and hobby welding

- Thin materials and short weld runs

Why Choose an MB15?

If comfort and ease of use are your priority, the MB15 is ideal. Its lightweight design reduces operator fatigue, making it perfect for detailed work and lower-amperage welding.

Parweld MB25 MIG Torch – Versatile All-Rounder

The Parweld MB25 MIG torch is one of the most popular choices for general workshop use. It offers a balance between power handling and usability.

Key Characteristics:

- Typically rated up to 184 amps (depending on duty cycle)

- More robust build than the MB15

- Improved heat resistance for longer welds

Best For:

- General fabrication

- Medium-thickness steel

- Workshop and trade use

- Longer welding sessions

Why Choose an MB25?

If you need a reliable torch that can handle a wide range of jobs, the MB25 is a great all-round solution. It's powerful enough for heavier work while still being comfortable to use for day-to-day welding.

Parweld MB36 MIG Torch – Built for Heavy‑Duty Welding

The Parweld MB36 MIG torch is designed for high‑amperage, industrial applications where durability and heat management are essential.

Key Characteristics:

- Typically rated up to 240 amps (depending on duty cycle)

- Thicker cable and reinforced torch neck

- Designed for sustained, high‑output welding

Best For:

- Heavy fabrication

- Structural steelwork

- Industrial and production environments

- Thick materials and long weld runs

Why Choose an MB36?

When welding at higher currents for extended periods, the MB36 offers the strength and cooling capacity needed to maintain performance and torch lifespan.

Which Parweld MIG Torch Is Right for You?

- Choose MB15 if you mainly weld thin materials or want maximum comfort and control.

- Choose MB25 if you need versatility for everyday workshop fabrication.

- Choose MB36 if you regularly weld thicker materials at higher amperages.

If you’re unsure which torch best matches your welder or application, our team is always happy to help you choose the right Parweld MIG torch for your setup.

Looking for Parweld MB15, MB25 or MB36 MIG torches or consumables? Get in touch or explore our range online to find the right torch for your welding needs.

End of Year Reflection 2025: What a Year It’s Been

Posted on 05/01/2026

As we’ve just come to the end of another busy year, it feels like the right time to pause, reflect and say a huge thank you to everyone who has been part of our journey. This year has been one of progress, learning and momentum across every part of the business.

Some of this year's highlights

- Thousands of orders shipped - from everyday essentials to specialist equipment, we’ve kept products moving out the door and into workshops across the UK.

- Another record‑breaking year on the website - more visitors, more orders and more customers choosing to buy online with us than ever before.

- New stock added to our range - including the arrival of Bessey clamps and GYS machines, expanding the options available to our customers.

- Training and development - many trainees are now fully coded in welding, a huge achievement and one we’re proud to support.

- Hands‑on team development - our own team took part in a MIG welding taster session and absolutely smashed it.

- Gas deliveries by the gallon - a steady stream of gas orders keeping fabrication, repair, and production work moving.

- Compliance and safety support - countless LEV tests, CP7 and CP47 inspections completed, helping customers stay safe and compliant.

Growing Our Community

We’ve also seen fantastic growth across our social channels this year. We’ve connected with many new faces from across the welding and fabrication industry.

If you're new here - hello and welcome Thank you for following, engaging and supporting us.

Thank You for Being Part of It

None of this happens without our customers, partners and team. Whether you've placed one order or hundreds, booked servicing, attended training or simply followed along online - we truly appreciate it.

As we look ahead, we’re excited to keep building on this momentum, expanding what we offer and continuing to support welders, fabricators and workshops in the year ahead.

Here's to a strong finish to the year and an even better one to come.

How to TIG Weld Aluminium: A Beginner-to-Intermediate Guide for 2025

Posted on 29/12/2025

TIG welding aluminium is one of the most challenging yet rewarding processes a welder can master – aluminium behaves very differently to any other metal such as steel. Without the right setup, prep and technique, this material will punish even small mistakes.

In this guide we will take you step-by-step through the entire process from machine settings and torch control to filler rod choice and troubleshooting. This guide is aimed at beginner to intermediate welders so whether you’re completely new to TIG welding aluminium or if you’re just looking to improve your weld quality, this article is for you.

Why Is Aluminium Harder To Weld Than Steel

1. It conducts heat extremely fast

Aluminium pulls heat away from the weld area quicker than steel. This means:

- You need more amperage

- The weld pool forms suddenly

- Thinner material overheats easily

2. The oxide layer melts at a far higher temperature

Aluminium oxide melts at around 2,000°C, while aluminium melts at around 660°C.

This is why:

- Cleaning is essential

- AC balance is needed to “break up” the oxide

- You must avoid dirty or oxidised surfaces

3. It has no colour change to warn you it’s about to melt

Unlike steel, aluminium does not glow as it heats. This makes heat control a major challenge for beginners.

4. It’s incredibly sensitive to contamination

Everything matters:

- Prep

- Clean gloves

- Clean filler rods

- Gas coverage

- Torch angle

Even small contaminants can cause porosity or black soot on the weld.

What You Need To Weld Aluminium

1. An AC/DC TIG welder

AC (alternating current) is required to:

- Remove the oxide layer

- Stabilise the arc

- Provide both cleaning and penetration

An excellent beginner friendly machine would be the Parweld XTT 212DI AC/DC Pulsed TIG Inverter Welder Package. It has advanced pulse TIG and synergic control modes, square wave AC TIG for optimal performance on aluminium and includes a TIG torch, regulagor and other accessories.

2. Pure argon gas (100%)

You can either use industry sized cylinders such as BOC Gases or Pure Argon Disposable Bottles – you would need a different regulator if you chose to use disposable cylinders.

3. The right tungsten

The best choice today is:

- Zirconiated (white)Tungsten for traditional AC use

These electrodes maintain a balled tip shape which is ideal for AC TIG welding, improving arc control and weld consistency.

4. A TIG torch with a gas lens kit

Gas lenses dramatically improve gas coverage, reduce turbulence, and allow longer tungsten stick-out - ideal for aluminium’s sensitivity.

5. Suitable filler rods

The two most common grades:

- 4043 Aluminium TIG Rods - smoother welds, easier for beginners

- 5356 Aluminium TIG Rods - stronger, better for structural work and fabrication

6. Proper PPE

Including:

Step-By-Step Guide To Welding Aluminium:

Step 1 (Preparing the Aluminium)

Prep is one of the biggest factors in weld quality, especially when welding aluminium. If you don’t nail your prep and remove contaminants, you are likely to get welding defects such as porosity (gas pockets which reduce integrity of the weld), slag and cracks.

1. Remove the oxide layer

Use:

- A stainless-steel wire brush dedicated ONLY for aluminium such as Abracs Scratch Brush For Stainless Steel

Or

- scrape with a carbide tool

2. Degrease thoroughly

Use:

- Acetone

- Isopropyl alcohol

Oils, fingerprints and coolant residue all cause porosity.

3. Abrade if needed

For thicker or heavily oxidised material, lightly abrade using:

- Scotch-Brite

- Fine aluminium oxide flap disc

4. Clean the filler rod too

Many welders skip this step and it often causes porosity issues.

Use:

- A Scotch-Brite pad to remove surface oxidation

- Clean rage to wipe with acetone to remove oils and dirt

Make sure you spin the rod as you wipe to ensure it's spotless before use.

Step 2 (Setting Up Your TIG Welder For Aluminium)

Settings vary by machine but these guidelines will get you very close and are a good rule of thumb to go by.

AC Balance

Controls the split between:

- Electrode positive (cleaning)

- Electrode negative (penetration)

A common starting point is 70% Penetration / 30% Cleaning for general use.

You can adjust it to add more cleaning (e.g. 60/40) for dirtier aluminium to remove stubborn oxides. The key is to find the sweet spot where you get enough cleaning for a good weld without sacrificing tungsten integrity or arc stability.

AC Frequency

AC frequency controls the arc’s focus and heat.

A solid starting point for most jobs is around 100-120 Hz as it is a versatile all-around setting.

From this point you can adjust depending on your requirements:

Higher frequencies (e.g. 150–250+ Hz):

- Very focused and arrow the arc

- Improve control

- Reduce the wandering arc effect

Higher frequencies are ideal for thin aluminium, tight joints and stacking beads.

Lower frequencies (e.g. 50-80 Hz:

- Produce wider beads

- Increase heat in the part

Lower frequencies are ideal for thick aluminium or when you need to lay down more metal / repair larger areas

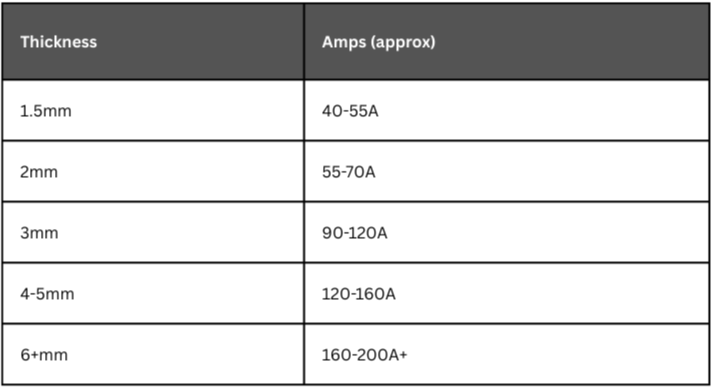

Amperage Settings by Thickness of Material

Below is a general guide on what amperage to set your machines at based on material thickness:

Tip: Get a foot pedal as it gives you the control you need as aluminium suddenly ‘opens up’ into a molten pool.

Gas Flow

Set flow rate around:

- 6–8 LPM with a standard cup

- 8–12 LPM with a gas lens

- Increase slightly in drafty conditions

Tungsten Choice and Prep

- Use 2.4mm for most aluminium work (2-6mm)

- Use 3.2mm for thick aluminium (6mm+)

- Use 1.6mm for thin material (up to 2mm)

Step 3 (Technique: Torch Angle, Body Position & Filler Control)

Torch Angle: Aim for 10–15° push angle

Never pull, always push aluminium TIG.

A pulling torch angle reduces gas coverage and causes:

- Soot

- Porosity

- Oxide contamination

Arc Length: Aim for 1–2mm arc length

This is the distance between the electrode and the workpiece – you want to keep it tight as a long arc:

- Overheats the part

- Causes black soot

- Makes the bead uncontrollable

Filler Rod Control

Establish a molten puddle first, then dip the rod into the leading edge (the front, furthest-advanced part of the molten weld puddle) with a consistent, rhythmic "dab and move" .

If filler melts in your hand:

- Your arc is too long

- You’re feeding too close to the tungsten

- You’re using too thin a rod for the heat input

Travel Speed

Aluminium needs a steady pace:

- Too slow = overheating

- Too fast = cold lap

Consistency matters more than speed.

Step 4 (Common Problems & How to Fix Them)

1. Black Soot on the Weld

Usually caused by:

- Wrong AC balance

- Incorrect torch angle

- Insufficient gas flow

- Dirty aluminium

2. Porosity

Common causes:

- Dirty filler rods

- Contaminated base metal

- Drafts blowing gas away

- Moisture in the material

3. Lack of Penetration

Fixes:

- Increase EN on AC balance

- Increase amperage

- Reduce travel speed

4. Edges Melting Away

Often caused by:

- Too much EN (too much cleaning)

- Too slow travel

- Too much heat concentrated on the edge

5. Tungsten Contamination

Happens when:

- Arc length is too short

- You dip the tungsten

- The filler touches the tip

Final Tips for Clean Aluminium TIG Welds

- Keep everything immaculately clean

- Always use 100% argon

- Use a gas lens where possible

- Don’t rush prep - it’s half the job

- Practice on 2–3mm plate before attempting thin sheet

- Control heat at the end of the weld by tapering off the pedal

Learning to TIG weld aluminium takes time but the payoff is SO worth it. With the right setup and the right habits, your welds will become cleaner, brighter and more consistent.

Need Help Choosing an AC/DC TIG Setup?

Whether you're learning TIG for the first time or upgrading your workshop, our team at Welding Superstore can recommend the right machine, torch, tungsten and consumables for your needs.

Contact us now.

Need Welding Supplies Fast? Click & Collect Available from Our Telford Showroom

Posted on 22/12/2025

When you’re in the middle of a job and realise you’re missing something essential, waiting for delivery simply isn’t an option. That’s why Click & Collect is available from our Telford showroom giving you a quicker, easier way to get the tools, consumables or equipment you need fast.

How Click & Collect Works

Getting your order couldn’t be simpler:

- Shop online as normal.

- At checkout, select ‘Collection from Store’.

- We’ll prepare your order ready for pickup - often within the hour.

- Pop into our Telford showroom and collect whenever it suits you.

Hundreds of Products, Ready in Under an Hour

Whether it’s welding wire, helmets, gloves, gas equipment, abrasives or MIG torch consumables, we keep hundreds of products in stock ready to collect. That means most orders can be ready in less than an hour - perfect for tradespeople, workshops and anyone working to a tight deadline.

Why Choose Click & Collect?

- No downtime waiting for delivery

- Instant access to our most popular products

- Convenient location on Telford’s Stafford Park Industrial Estate

- Expert advice available in-store from our experienced team

- Ideal for urgent jobs, last-minute repairs and workshop restocks

Find Us in Telford

Our showroom is easily accessible with free parking available. Simply head to our premises on Stafford Park Industrial Estate and collect your order at the counter - quick, easy and hassle-free.

Welding Superstore Christmas Opening Hours 2025

Posted on 15/12/2025

As we get closer to Christmas, we want to make sure all our customers have the information they need to plan orders, collections and deliveries. Below you’ll find our full festive opening times and final order deadlines for December.

Christmas Closure Dates

Our team will be taking a well-earned Christmas break and Welding Superstore will be closed from Monday 23rd December at 2pm.

We’ll fully reopen in the New Year on Thursday 2nd January at 8am and all online orders placed over the break will be dispatched once we’re back.

Last Order Dates for Pre-Christmas Delivery

To ensure you get your items before Christmas, please keep these final order deadlines in mind:

Telford Deliveries (BOC, Flogas, Local Account Customers)

- Last Order Date: Thursday 19th December, 5pm

Courier Dispatch

- Last Order Date: Sunday 22nd December, 3pm

Any orders placed after these times will be processed when we reopen on 2nd January 2025.

Need Welding Consumables Before The Christmas Break?

The run-up to Christmas is always busy, especially for workshop essentials, welding gear and last-minute stocking fillers. If you’re unsure whether an item can be delivered before the holidays or if you need help choosing the perfect gift for a welder, our team is here to help until 23rd December at 2pm.

Thank You & Merry Christmas

From everyone at Welding Superstore, thank you for supporting us throughout 2025. We wish you a very Merry Christmas and a Happy New Year and we look forward to supplying your workshop needs in 2026.

What Shade Do I Need for Different Welding Processes? (2025 Guide)

Posted on 08/12/2025

Choosing the correct welding shade level is one of the most important steps in protecting your eyes from arc flash. Whether you’re MIG, TIG, MMA or plasma cutting, selecting the right welding helmet shade ensures you can see the weld pool clearly while staying safe. In this 2025 guide we’ll break down exactly what shade numbers you need for different welding processes and what to look for when buying a modern auto-darkening welding helmet.

Why Welding Shade Levels Matter.

Welding produces intense ultraviolet (UV) and infrared (IR) radiation. Using the wrong shade can lead to eye strain, poor visibility or even photokeratitis (welder’s flash).

Modern auto-darkening helmets make shade selection easier, but it’s still crucial to understand the correct range for your process.

Recommended Welding Shade Levels by Process

MMA (Stick) Welding – Shade 9–13.

Stick welding creates a bright arc and heavy spatter, so darker shades are essential.

- 40–80 amps: Shade 9

- 80–200 amps: Shade 10–12

- 200–400 amps: Shade 13

For variable amperage work, an auto-darkening helmet with a full Shade 9–13 range is ideal such as the Parweld XR935H Black Light Reactive Welding & Grinding Helmet.

MIG/MAG Welding – Shade 10–13

MIG welding produces a consistent, bright arc. Shade requirements depend on metal thickness and amperage:

- Low-amp MIG: Shade 10

- Medium MIG (around 200A): Shade 11–12

- High-amp MIG (300A+): Shade 13

Look for helmets with fast reaction time and adjustable sensitivity for workshop environments such as Parweld XR942H Panoramic Welding & Grinding Helmet.

TIG Welding – Shade 8–13

TIG welding has a lower, more focused arc but requires greater visual clarity.

- Below 50 amps: Shade 8

- 50–150 amps: Shade 9–11

- 150+ amps: Shade 12–13

A helmet with true colour technology and excellent low-amp response is vital for TIG such as Parweld XR938H Blue Large View Light Reactive Welding and Grinding Helmet, also available in red, silver and graphite.

Plasma Cutting – Shade 5–9

Plasma cutting varies with the type of machine and material thickness.

- Handheld light cutting: Shade 5–6

- Medium cutting: Shade 7–8

- Heavy industrial cutting: Shade 9

Ideal to pair with helmets that feature a dedicated cutting mode such as Parweld XR942H Panoramic Welding & Grinding Helmet.

Grinding – Shade 3–4

Shade 3 or 4 is recommended for grinding, allowing clear visibility while still providing basic eye protection. Many auto-darkening helmets offer a grind mode so you can swap tasks instantly without taking the helmet off.

What to Look for in a Quality Welding Helmet

To stay safe and productive, choose a welding helmet with:

- Auto-darkening filter with Shade 9–13 range

- True Colour lens technology

- Variable sensitivity and delay controls

- A large viewing area

- Comfortable headgear for all-day use

Explore our full range of welding helmets, including the XR938H and XR942H to find the perfect option for your setup.